Embodied Carbon Reduction Challenge

Northland Newton Development, Building 7, Newton, MA

Reducing embodied carbon emissions by optimizing structural design and reducing reliance on concrete and steel

Project Overview

The design team behind Building 7 at Northland Newton Development—the former industrial complex being converted into a sustainable, efficient, and healthy mixed-use community—saw the opportunity to go above and beyond and decrease embodied carbon emissions through the strategic use of mass timber.

This project is helping to establish a standard for reducing embodied carbon per square meter of usable internal floor area over a 50-year period. It showcases innovative structural solutions—like cross-laminated timber (CLT) for floors, shear walls, and roofs complemented by steel and concrete where they’re essential for specific structural needs.

SWA entered the Building 7 case study in the Massachusetts Clean Energy Center (MassCEC) and Built Environment Plus (BE+) Embodied Carbon Reduction Challenge for cost-effective and replicable strategies from new construction and major renovation projects. The team earned a runner-up prize and together, the 16 participating projects reduced embodied carbon emissions by a total of ~25K metric tons—the same as the carbon sequestered in 410K+ tree seedlings grown for 10 years.

Building Details

Building 7:

- Model Floor Area: 83,017 SF

- Building Height: 58′

- 55 units

Project Team

Developer: Northland Investment Corp.

Construction Manager: Cranshaw Construction

Architect: Stantec Architecture

Structural: Odeh Engineers

Timber Design Assist: TimberLab

Sustainability Assist: Lambert Sustainability

Services Provided

- Certification Support & Verification

- Envelope Enclosure Consulting

- Energy Modeling

Certifications

LEED

Passive House Institute (PHI)

Zero Energy Ready Home

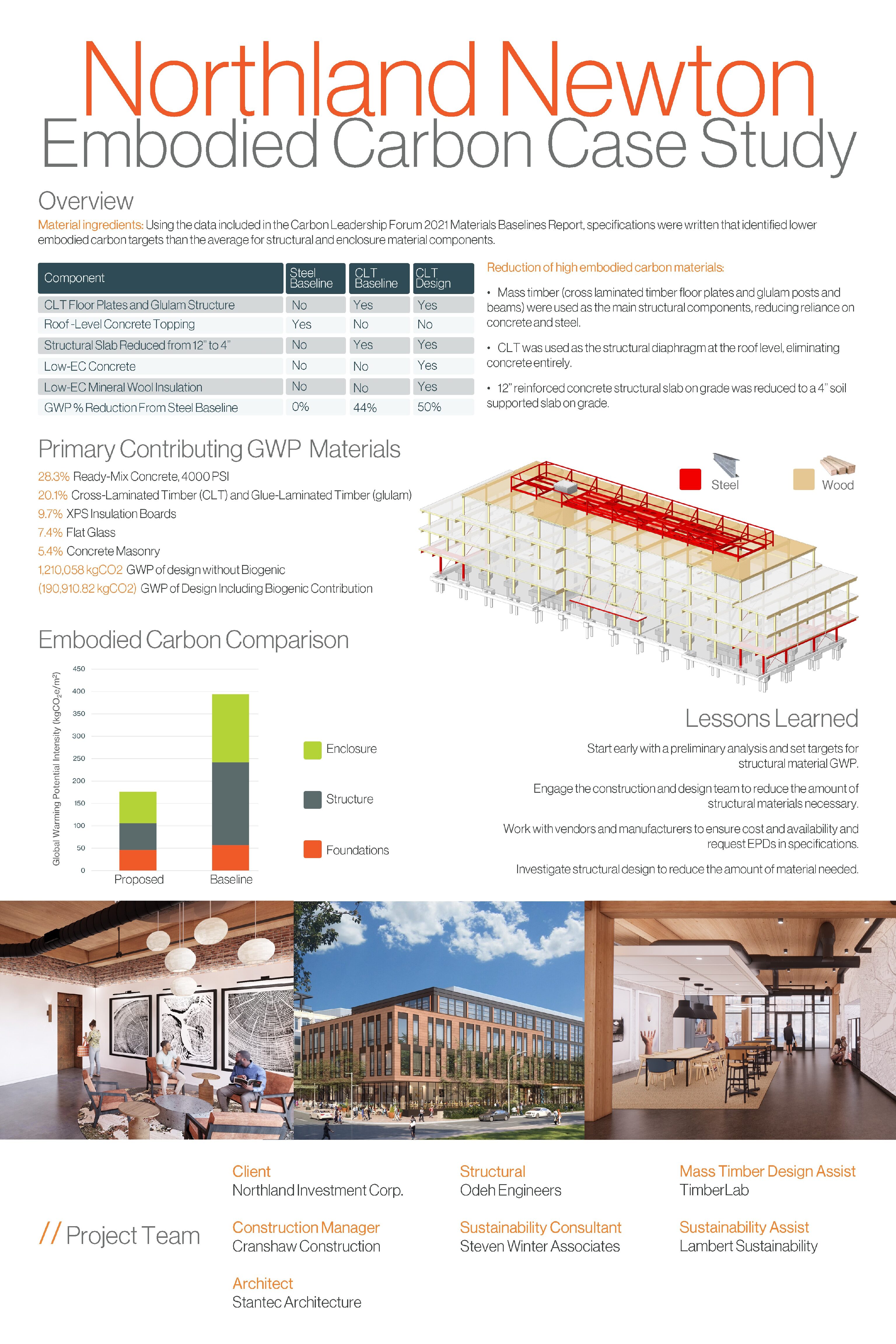

Material Strategy

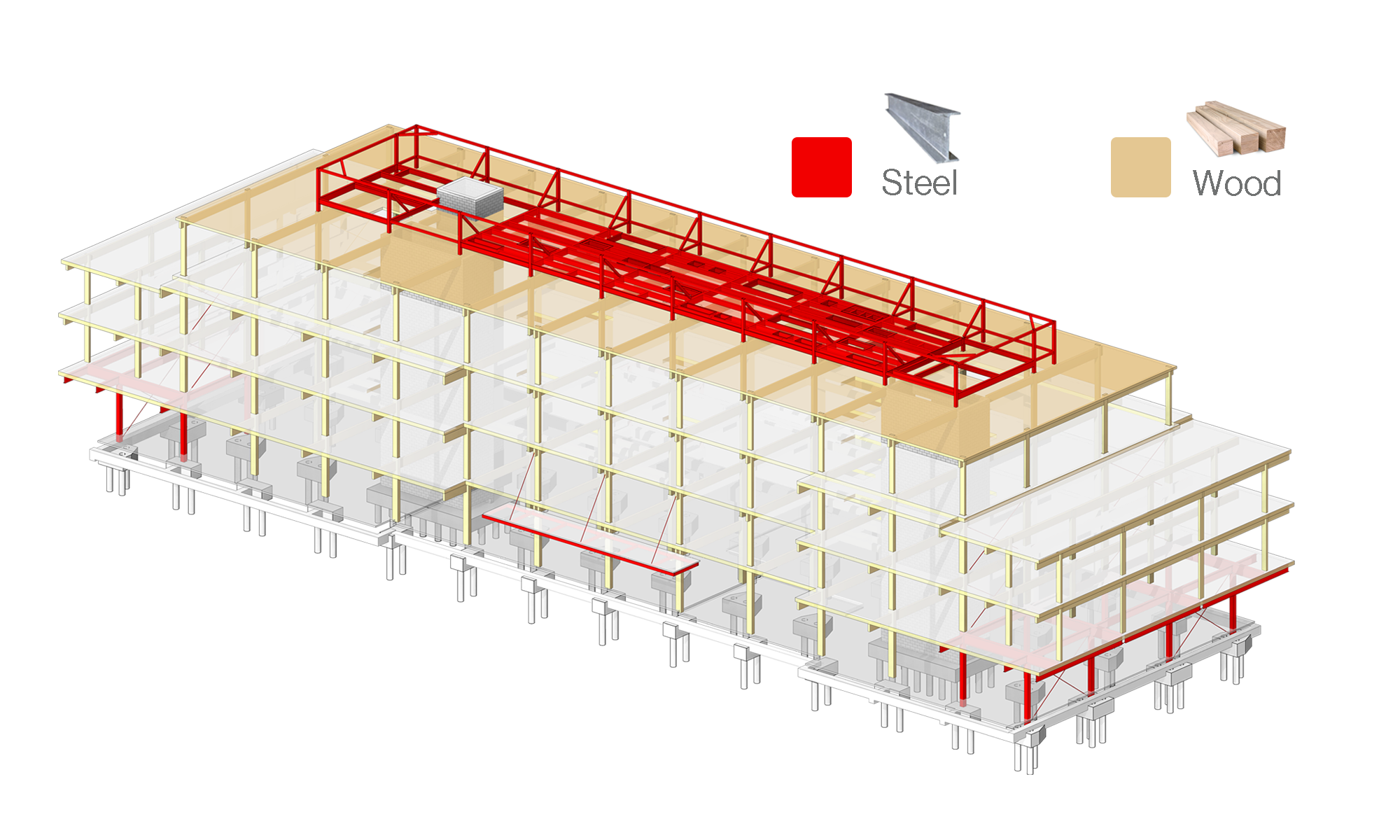

The amount of concrete in Building 7 was reduced at the slab and the roof level by introducing CLT floor plates. The concrete in the slab was reduced from a traditional 12″ reinforced concrete structural slab on grade to a 4″ soil-supported slab on grade.

To accommodate potential settlement of the slab, interior finishes were detailed accordingly: At the roof level, concrete was entirely eliminated by using CLT as the structural diaphragm.

The structural engineer’s strategy involved using the appropriate material for each location and function, resulting in the incorporation of a small amount of steel at cantilevers and some concrete in each floor plate.

In addition to reducing the quantity of material with a high GWP, specifications were edited to include embodied carbon targets for concrete, steel, gypsum board, and insulation. These specifications are based on the Carbon Leadership Forum (CLF) 2021 baselines for global warming potential limits. The general contractors are strictly monitoring submittals throughout construction to ensure products meet these GWP targets.

SWA conducted a whole building life cycle assessment (LCA), highlighting the significant reductions in GWP achieved compared to the baseline steel building.

Impact Assessment

GWP measures the impact of greenhouse gas emissions on surface temperatures at local, regional, and global levels. It indicates how these emissions contribute to climate change as well as related environmental issues like acidification and smog. Often referred to as the “carbon footprint,” GWP evaluates the potential for climate change associated with various materials and processes.

In SWA’s analysis, the major contributors to GWP emissions are as follows:

- Ready-mix concrete (4000 PSI): 28.3%

- Cross-laminated timber (CLT) and glue-laminated timber (Glulam): 20.1%

- XPS insulation boards: 9.7%

- Flat glass: 7.4%

- Concrete masonry: 5.4%

The total GWP for Building 7 was calculated at 1,210,058 kg CO2e.

SWA incorporated an analysis of biogenic contributions into the GWP calculation to account for the carbon sequestered in wood during its growth, emphasizing a greater impact as compared to concrete and steel. This analysis covered cradle to gate stages (A1-A3), which include raw material supply, transportation, and manufacturing. The stored biogenic carbon content was calculated as 1,360,529 kg CO2e.

By accounting for the carbon storage within the proposed timber building (1,210,058 kg CO2e), the overall embodied carbon, when considering this carbon storage, is reduced by -150,471 kg CO2e. This indicates that the wood structure has sequestered more CO2 than was emitted throughout its lifecycle.

The embodied carbon comparison shows a significant reduction from a traditionally steel-built baseline of 394 kg CO2e/m2 to a proposed design with 197 kg CO2e/m2, marking a total reduction of 50%.

The calculations described above were performed with the One Click LCA tool. The software is fully compliant with EN 15978 standard. One Click LCA has been third-party verified by ITB for compliancy with the following LCA standards: EN 15978, ISO 21931–1 and ISO 21929, and data requirements of ISO 14040 and EN 15804.