- March 14, 2018

- 0 Comments

- In Certifications & Programs High-Performance Construction

- By Steven Winter Associates

*click here to read Part 1 of this blog

In climates with significant heating and/or cooling seasons, Passive House projects must have a balanced heat or energy recovery ventilation system. These systems use a heat exchanger to transfer heat and moisture between the outgoing return and incoming outdoor airstreams. The operation of recovery ventilators reduces the energy required to heat and cool decreasing the building’s carbon footprint. Project teams can select either:

- Heat Recovery Ventilators (HRV) that transfer heat from the return air stream to the outside air stream; or,

- Energy Recovery Ventilators (ERV) that transfer heat and moisture from the return air stream to the outside air stream.

Deciding between an HRV and an ERV gets more complex when the Passive House concept is scaled from a single-family home to a multifamily program. What the industry has learned from the development of airtight buildings and programs such as Passive House and R2000, is that indoor relative humidity must be controlled through continuous ventilation. The extremely air tight building envelope required of a Passive House, combined with high internal moisture gains from an occupant dense multifamily program (coming from occupants, kitchens and bathrooms), forces additional moisture management considerations during mechanical ventilation design. Maintaining acceptable interior relative humidity in both the heating and cooling season is paramount for building durability and occupant comfort. It’s appropriate that Passive House professionals claim this simple motto: “Build tight, ventilate right!”

In New York City where the multifamily Passive House market is rapidly growing, there is a significant heating season and a demanding cooling season with high humidity (Climate Zone 4A). With this seasonal variation, there are four primary operating scenarios for an HRV or ERV that need to be considered during design:

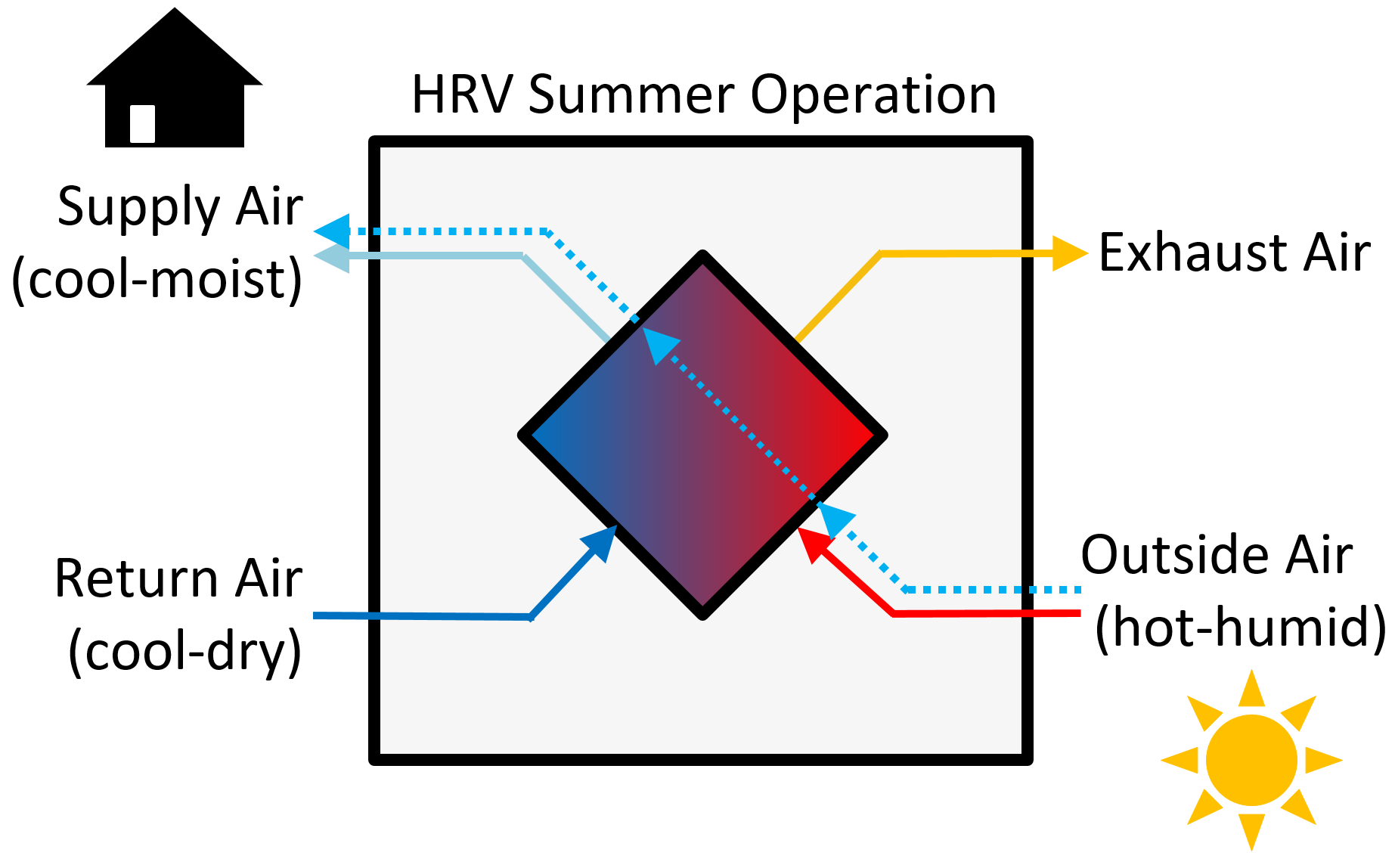

Summer Condition – HRV

An HRV operating in the summer (hot-humid exterior air and cool-dry interior air) introduces additional moisture to the building through ventilation. Heat is transferred from the incoming outside airstream to the return airstream leaving the building which cools supply air, but exterior moisture is not removed from the incoming air. The building’s dehumidification load increases as a consequence of additional moisture from the outdoor air.*CON*