Blog

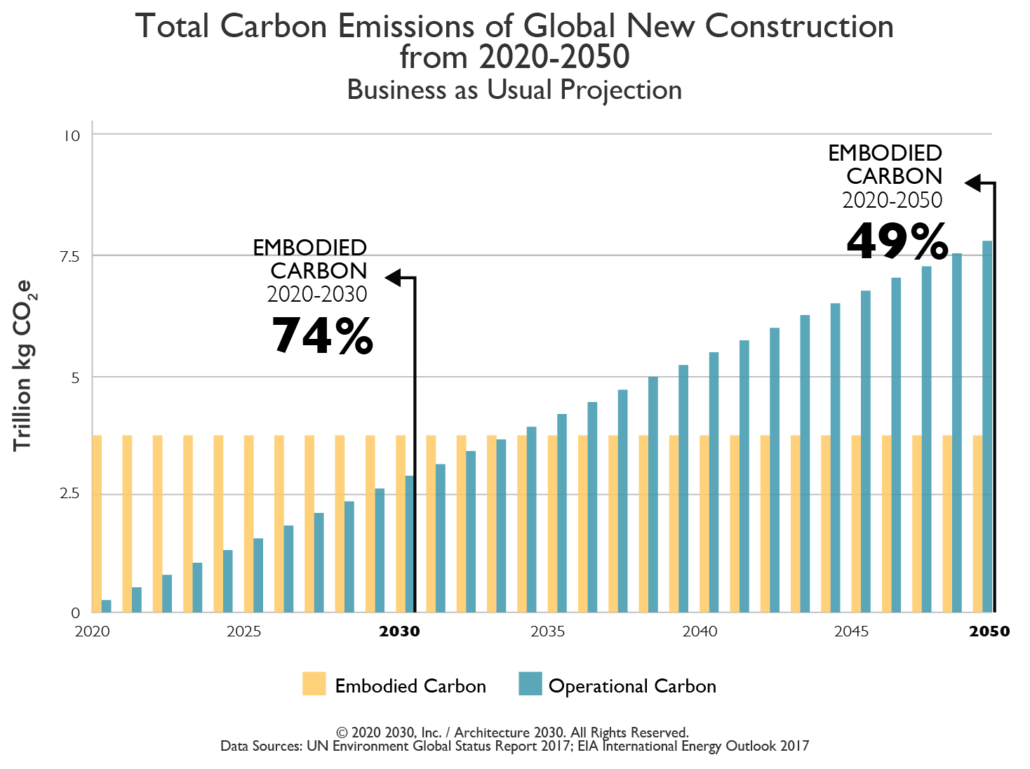

To meet the goals of the Paris Climate Agreement, we must make decisions that take into account both embodied carbon and operational carbon.

To meet the goals of the Paris Climate Agreement, we must make decisions that will result in the greatest near-term carbon savings. This means taking into account both embodied carbon—those upfront emissions associated with the extraction, manufacture, transportation, and assembly of building materials—as well as the carbon that’s emitted over the course of the building’s operational phase.

We can build a high-performance building with very low operational emissions, but if its embodied emissions are so high that even if it’s a net-zero energy building (meaning it has net-zero operational energy consumption) it would take decades for the building to reach net-zero carbon (meaning it has net zero whole-building lifetime carbon emissions), we’re not actually helping to solve the critical issue of near-term carbon.

If they build new:

Operational Emissions

To reduce the project’s operational carbon impact, the goal is a net-zero energy level of performance. A tried-and-true methodology for this is to reduce loads and maximize efficiency.

Embodied Emissions

What about the embodied carbon emitted in the construction of the building? With new construction, reducing this embodied carbon impact, which often makes up between 30-60% of a building’s whole life carbon, will be the greater challenge. Fortunately, the embodied carbon of a building project can be reduced 10-20% without adding to construction costs.

Typically, the structure accounts for 70-80% of a new building’s total embodied emissions. But once structural materials are in place, they generally stay in place and have the lifetime of the building to amortize this carbon debt.

Structure

If using concrete:

If using steel:

If using wood:

Enclosure

Here things get tricky. The enclosure system is critical to achieving a net-zero energy building as it has a huge impact on the building’s loads and the efficiency of its systems. But what are the potential embodied carbon implications of constructing a high-performance envelope? If decarbonization is the goal, when making design decisions it is crucial to evaluate the implications for both operational carbon and embodied carbon alongside each other. This means looking at the building as a whole and accounting for all the ways in which its different components interrelate. The only really effective way to make informed design decisions to reduce carbon is with whole-building lifecycle assessment (WBLCA).

For example, envelope insulation has a huge impact on the building’s operation and serves several critical purposes beyond thermal performance. But some types of insulation (EPS, XPS, Polyiso, spray foam) have high embodied carbon. Is it as simple as avoiding these products? No. To learn why, read the upcoming post, Five Principles for Low Embodied Carbon Buildings.

That said, there are some general guidelines that all projects can follow to reduce the embodied carbon impact of the enclosure:

Frequent replacement of enclosure components adds significant embodied emissions, so design the envelope to be as durable as possible by using reliable and repairable materials. Use envelope commissioning to ensure these materials are correctly assembled and protected from damage.

If they adapt an existing building:

Without the need to manufacture and construct entirely new structural and enclosure systems, building reuse can dramatically decrease a project’s embodied carbon emissions. In fact, building reuse will almost always beat out new construction for lower whole life carbon emissions. Remember that it can take up to 80 years for a new building that’s even 30% more efficient than an average-performing existing building to offset due to its higher operational performance and the embodied carbon emissions related to the construction process.

But what about the operational emissions of the existing building selected for reuse? What will be needed to retrofit an existing building to achieve net-zero energy?

Operational Emissions

Depending on the conditions of an existing building, the task of cost-effectively retrofitting for net-zero energy performance is often well within reach and represents the path to the greatest overall avoided emissions.

In some cases, the easiest way to eliminate operational emissions of an existing building may be to convert the building to all-electric and source the electricity from 100% renewable sources. Options for on-site renewables may be more limited for existing buildings. For example, the existing roof may not be able to accommodate the added weight of a new PV system without additional structural support, which could carry significant embodied carbon cost.

In some cases, the easiest way to eliminate operational emissions of an existing building may be to convert the building to all-electric and source the electricity from 100% renewable sources. Options for on-site renewables may be more limited for existing buildings. For example, the existing roof may not be able to accommodate the added weight of a new PV system without additional structural support, which could carry significant embodied carbon cost.Embodied Emissions

Assuming the existing structure and enclosure will satisfy the building’s new use, a greater focus for reducing embodied emissions will shift to the interior materials.

A “hot spot” study of the proposed renovation design can be employed to identify the materials that will have the largest impact on embodied carbon. Common high-impact interior materials include:

Whether the community decides to build new or reuse an existing building, a net-zero carbon outcome depends on a holistic, whole life carbon approach. Keep an eye out for a follow-up post titled Five Principles for Low Embodied Carbon Buildings on what this means in practice.

Contributors: James Wilson, Sustainability Consultant; Catherine Paplin, Senior Building Enclosure Consultant

Steven Winter Associates