- February 07, 2019

- 0 Comments

- In Existing Building Performance Occupant Health & Wellness Residential Home Performance

- By Robb Aldrich

Everyone pretty much gets that continuous (or very frequent) ventilation is necessary in high-performance homes. And – at least in theory – most people get why balanced, heat recovery ventilation is better (than unbalanced and/or without heat recovery). But the devil’s in the details.

A couple years ago we started an R&D project with funding from DOE’s Building America program, and one of the first steps was interviewing several developers about ventilation (single- and multi-family residential, mostly on the East Coast). For none of these developers were HRVs or ERVs standard.[i] They all had some experience with ERVs, however, and when asked about these experiences the word “nightmare” came up shockingly often.

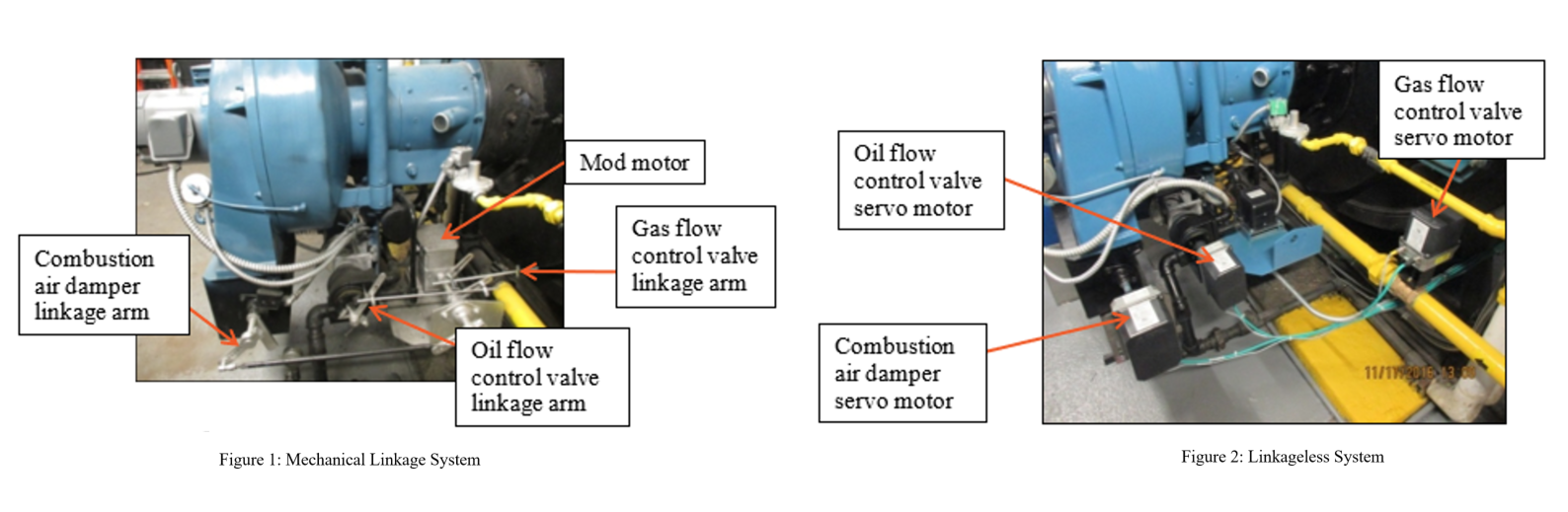

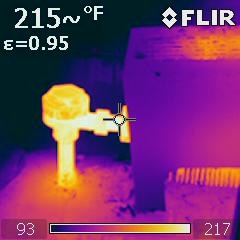

The ERVs on the market now can certainly work well in the right application, but we see problems more often than not. One of the biggest challenges is trying to add ERVs on to central heating/cooling systems in homes. Most ERVs aren’t really designed for this, and here’s what we see:

- Ducts connected to the wrong places! Outlet and inlet ducts get reversed, or the supply air from the AHU getting exhausted (sad how often this happens).

- ERVs are attached to supply and/or return trunks of the AHU. Unless the AHU fan is running constantly (or whenever the ERV is turned on), outdoor air comes into the AHU and is sucked right back out the ERV exhaust.

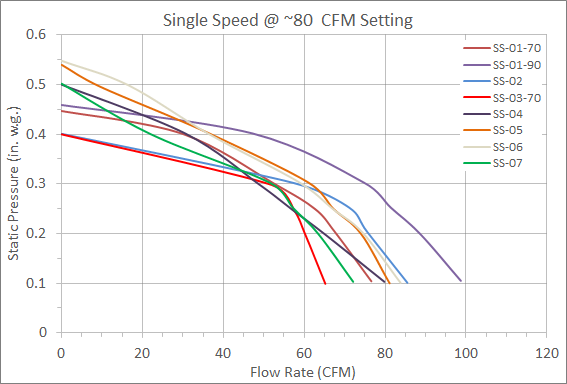

- If the AHU fan is turned on, the relatively small fans in the ERV can’t successfully compete with the big AHU fan. People don’t get the ventilation flow rates they want and/or the flows are very unbalanced.

- AHU fans can use A LOT of electricity. Hundreds of Watts is common – I’ve measured over 1 kW (though this is changing – more below).

Even if installers follow manufacturer instructions for attaching ERVs to AHUs, they could still end up with low flows, unbalanced flows, or high electricity consumption. Through this DOE R&D effort, we’re trying to do better.

(more…)