- March 08, 2018

- 0 Comments

- In Existing Building Performance High-Performance Construction

- By

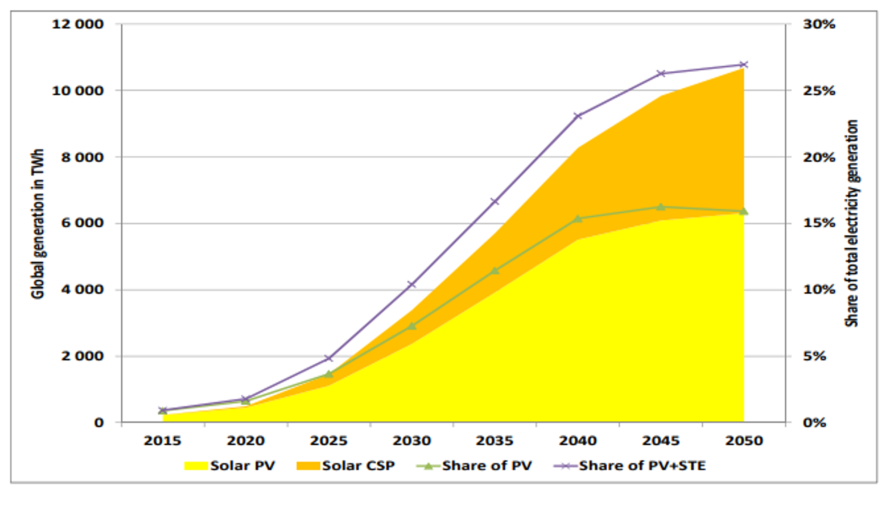

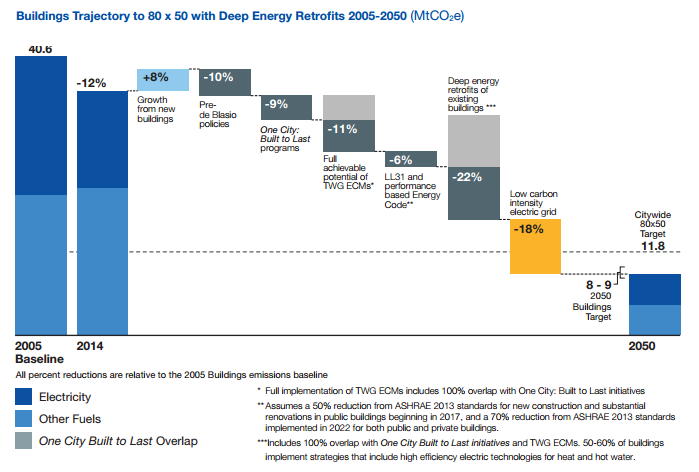

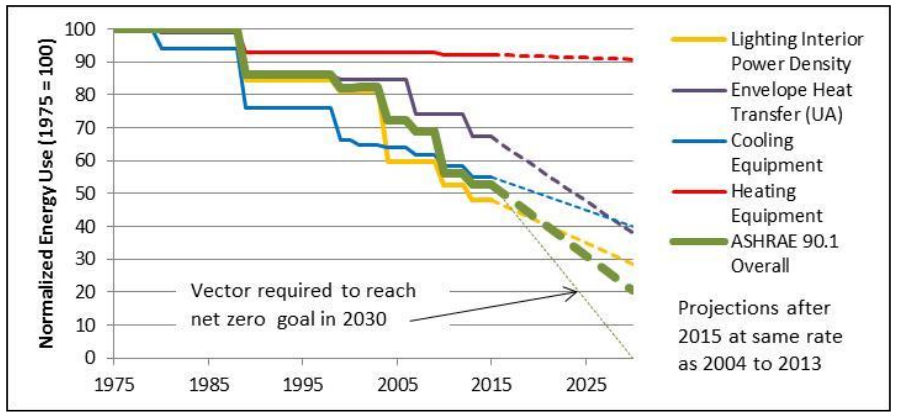

It has been clear for some time that energy codes are on course to require carbon-free buildings by 2030. Adoption at the local level will see some areas of the country getting there even sooner. For example, California has set net zero goals for its residential code by 2020. These developments have accelerated the debate about the effectiveness of energy modeling versus performance-based approaches to compliance.

Improvement in ASHRAE Standard 90/90.1 (1975-2013) with Projections to 2030. Courtesy of Pacific Northwest National Laboratory 2015

Let’s start with energy modeling, where change is coming for the better. In the past, the energy modeling community has been required to continuously respond to energy code cycle updates with new baseline models. That is, the bar for uncovering savings would be increased each and every time a new energy code was adopted. Following a code update, program staff and the energy modeling community would have to go through another learning curve to determine where to set a new bar and how to model the changes. (more…)