- February 14, 2018

- 0 Comments

- In Existing Building Performance High-Performance Construction

- By Andrea Foss

Montgomery County, Maryland recently passed new green building requirements, including adoption of the 2012 International Green Construction Code. Montgomery County was one of the first jurisdictions in the country to enact a green building law in late 2007. Now, county officials have repealed the original law and replaced it with Executive Regulation 21-15 that will likely reduce requirements for many new buildings.

New Requirements

There are some pretty big changes brought about by the new law, which took effect on December 27, 2017 and includes a six month grace period for projects already under design. New projects permitted after June 27, 2018 will need to comply with the following:

- Projects 5,000 gross square feet and larger must comply, lowered from 10,000 gsf.

- Buildings must meet the 2012 International Green Construction Code (IgCC), replacing the requirement that buildings must meet LEED Certified criteria.

- Residential projects under five stories must use ICC-700/NGBS at the Silver Energy Performance Level.

- R-2 and R-4 portions of Mixed-Use buildings may comply with ICC-700/NGBS and the non-residential portion shall comply with the IgCC or the entire building may comply with IgCC or ASHRAE 189.1

- R-1, non-residential and R-1/Mixed-Use projects may select IgCC, ASHRAE 189.1 or LEED Silver with eight points or more under the Whole Building Energy Simulation path.

- All buildings using the IgCC compliance pathway must achieve a Zero Energy Performance Index (zEPI) score of 50 or lower.

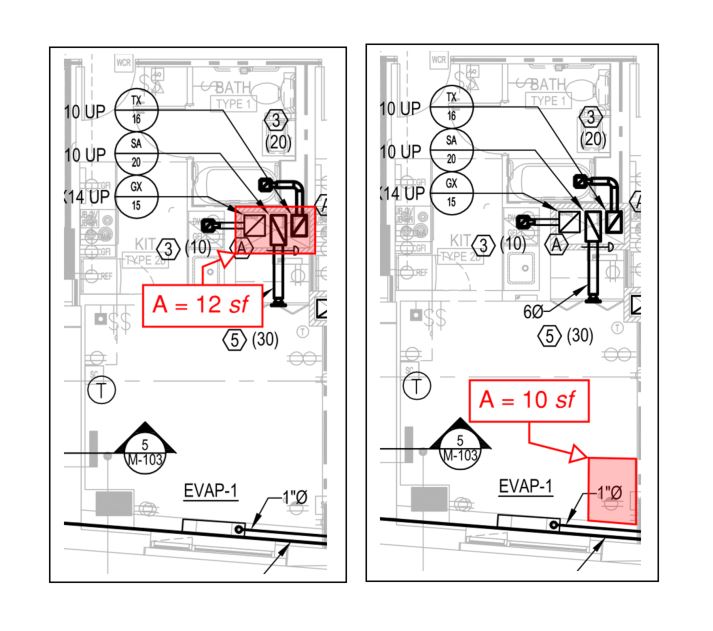

Common laundry rooms are typically provided in market rate and affordable multifamily buildings. Because there are no ventless clothes dryers available for commercial use in North America (such as condensing or heat pump dryers), Passive House (PH) projects must make do with standard coin-operated, conventional vented clothes dryers. With a conventional electric or gas vented dryer, ambient air from the laundry room is heated and blown into the dryer’s drum as it tumbles. This air picks up the moisture from the laundry and is exhausted – sending hot moist air and lint particles to the outside. For any dryer that exhausts more than 200 cfm and in common laundries that have several dryers, make-up air must be supplied to the room so the dryers have enough air to operate properly. This make-up air must then be heated or cooled and therefore, increases the building’s energy demand.

Common laundry rooms are typically provided in market rate and affordable multifamily buildings. Because there are no ventless clothes dryers available for commercial use in North America (such as condensing or heat pump dryers), Passive House (PH) projects must make do with standard coin-operated, conventional vented clothes dryers. With a conventional electric or gas vented dryer, ambient air from the laundry room is heated and blown into the dryer’s drum as it tumbles. This air picks up the moisture from the laundry and is exhausted – sending hot moist air and lint particles to the outside. For any dryer that exhausts more than 200 cfm and in common laundries that have several dryers, make-up air must be supplied to the room so the dryers have enough air to operate properly. This make-up air must then be heated or cooled and therefore, increases the building’s energy demand.