Blog

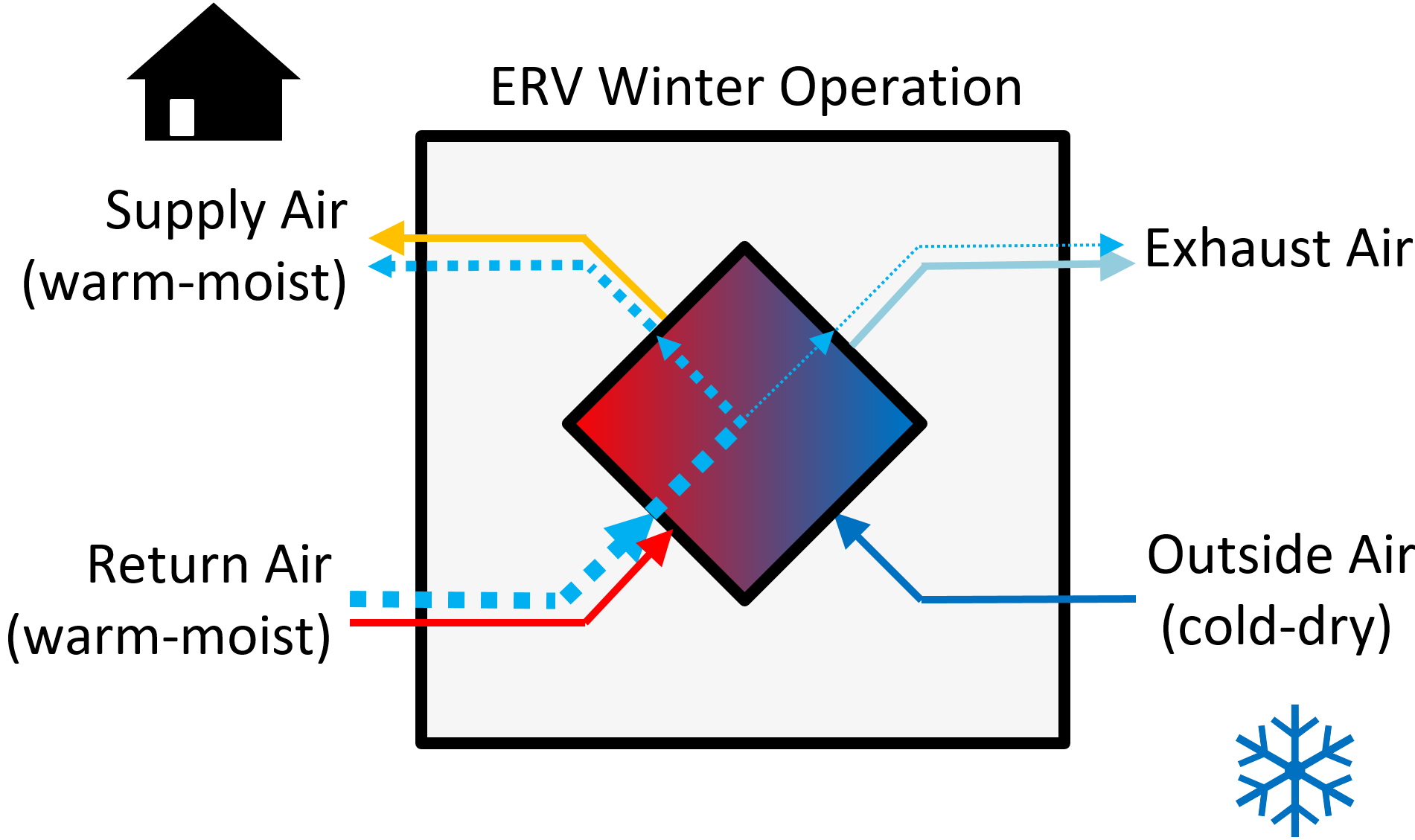

In climates with significant heating and/or cooling seasons, Passive House projects must have a balanced heat or energy recovery ventilation system. These systems use a heat exchanger to transfer heat and moisture between the outgoing return and incoming outdoor airstreams. The operation of recovery ventilators reduces the energy required to heat and cool decreasing the building’s carbon footprint.

*click here to read Part 1 of this blog

In climates with significant heating and/or cooling seasons, Passive House projects must have a balanced heat or energy recovery ventilation system. These systems use a heat exchanger to transfer heat and moisture between the outgoing return and incoming outdoor airstreams. The operation of recovery ventilators reduces the energy required to heat and cool decreasing the building’s carbon footprint. Project teams can select either:

Deciding between an HRV and an ERV gets more complex when the Passive House concept is scaled from a single-family home to a multifamily program. What the industry has learned from the development of airtight buildings and programs such as Passive House and R2000, is that indoor relative humidity must be controlled through continuous ventilation. The extremely air tight building envelope required of a Passive House, combined with high internal moisture gains from an occupant dense multifamily program (coming from occupants, kitchens and bathrooms), forces additional moisture management considerations during mechanical ventilation design. Maintaining acceptable interior relative humidity in both the heating and cooling season is paramount for building durability and occupant comfort. It’s appropriate that Passive House professionals claim this simple motto: “Build tight, ventilate right!”

In New York City where the multifamily Passive House market is rapidly growing, there is a significant heating season and a demanding cooling season with high humidity (Climate Zone 4A). With this seasonal variation, there are four primary operating scenarios for an HRV or ERV that need to be considered during design:

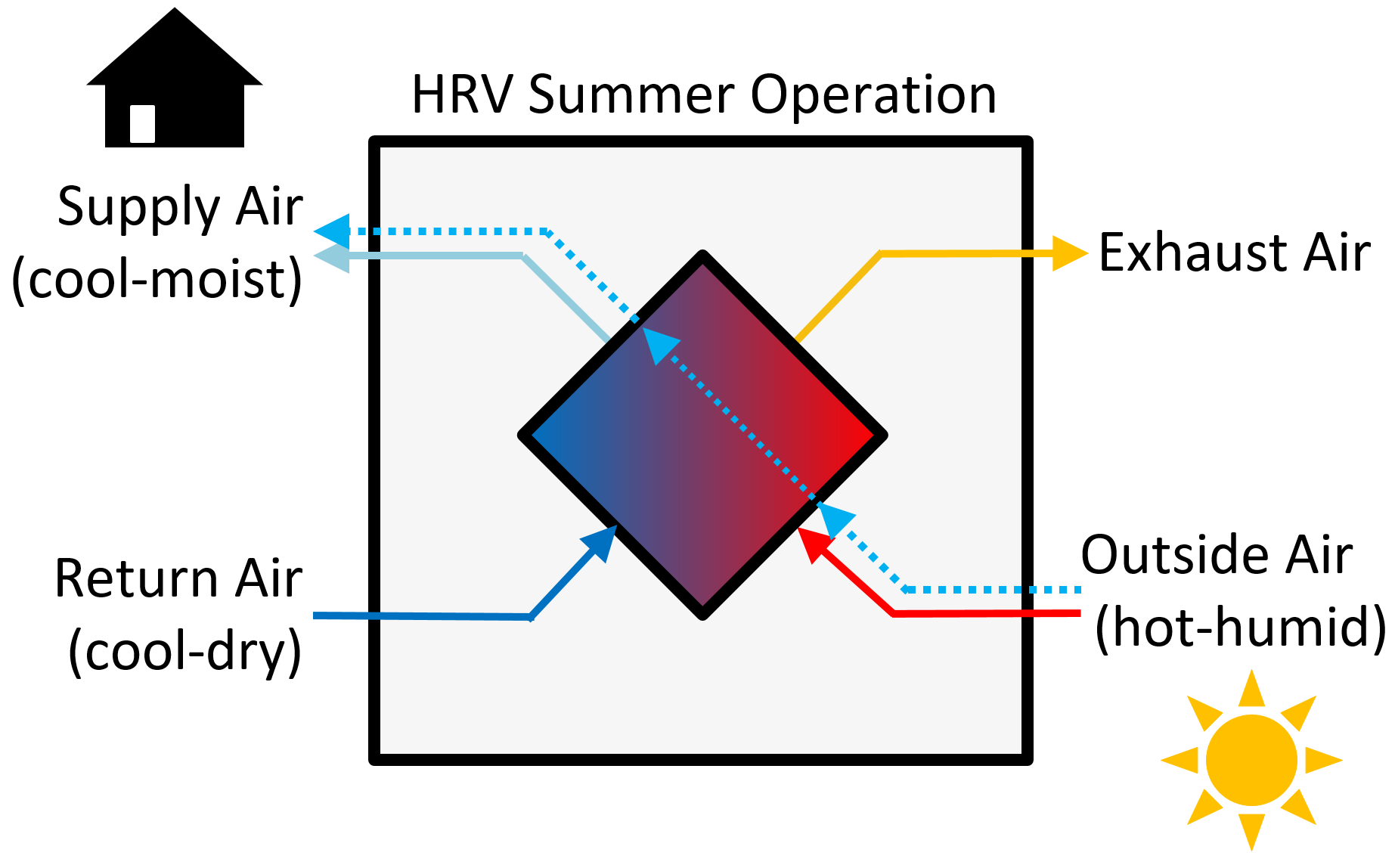

An HRV operating in the summer (hot-humid exterior air and cool-dry interior air) introduces additional moisture to the building through ventilation. Heat is transferred from the incoming outside airstream to the return airstream leaving the building which cools supply air, but exterior moisture is not removed from the incoming air. The building’s dehumidification load increases as a consequence of additional moisture from the outdoor air.*CON*

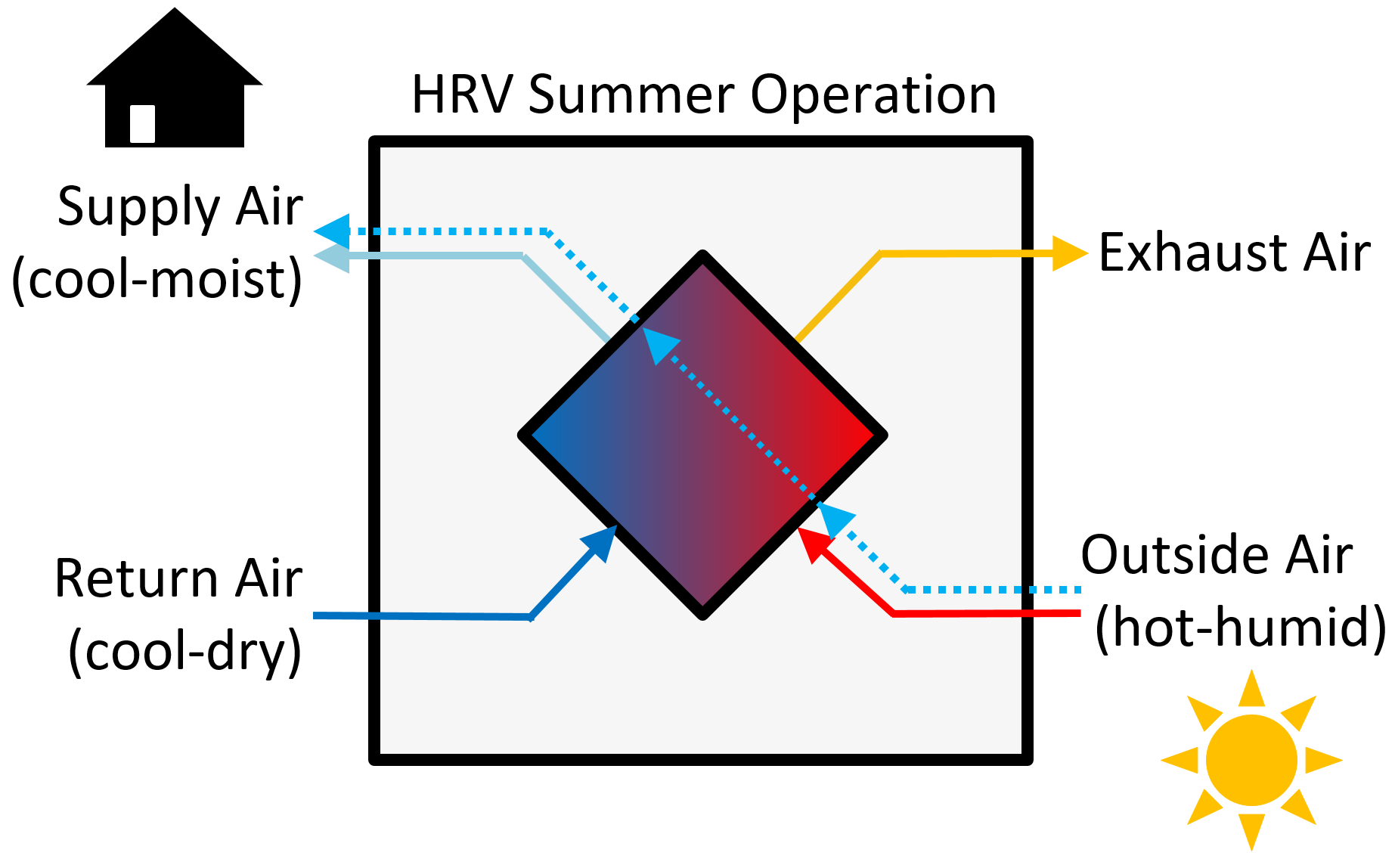

An HRV operating in the winter (cold-dry exterior air and warm-moist interior air) exhausts the moisture generated by building occupants. Heat is transferred between the two airstreams at the recovery core, but moisture in the return air is not transferred to the supply. As a result, controlling interior relative humidity in the winter can be less challenging with an HRV.*PRO*

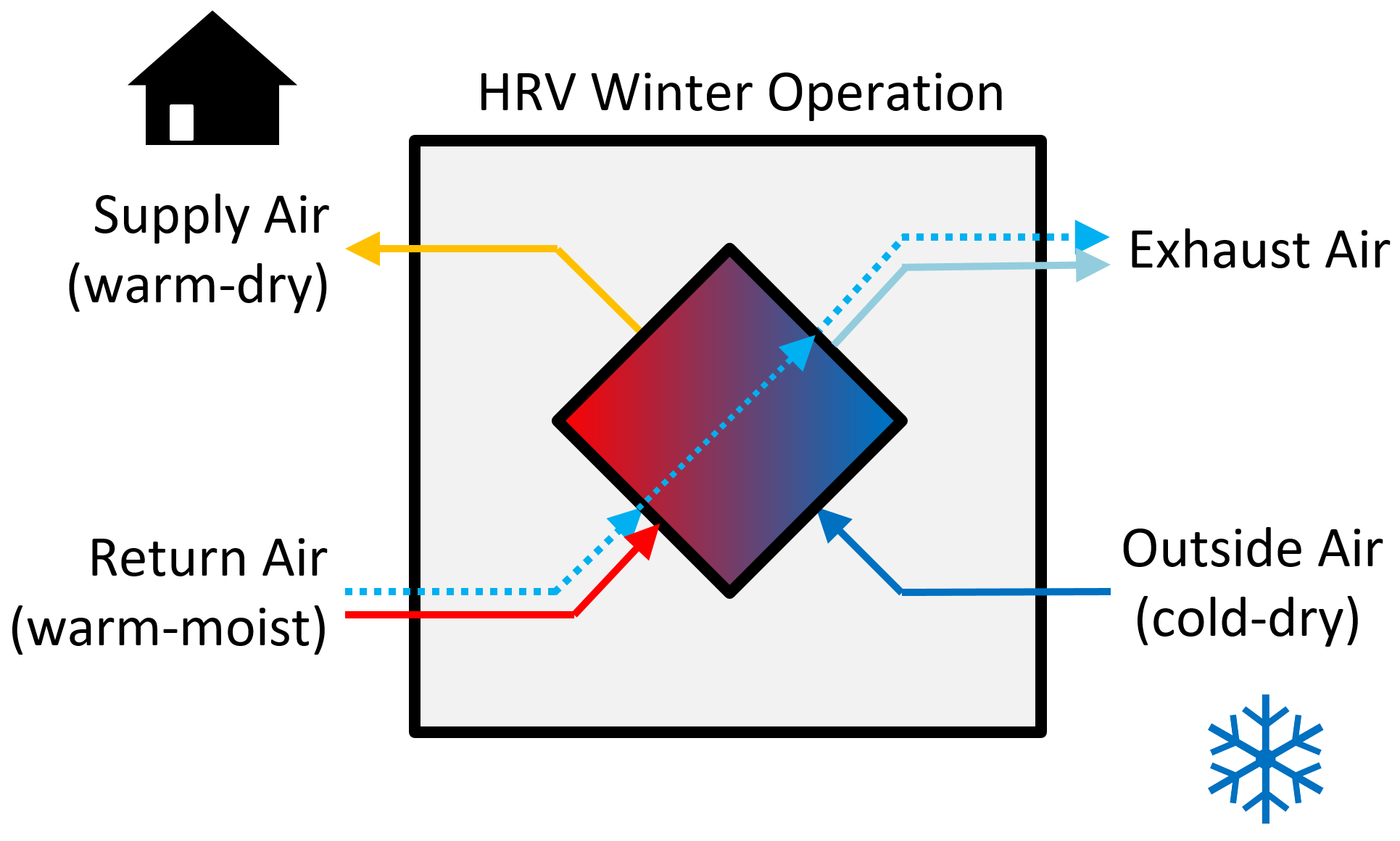

An ERV operating in the summer (hot-humid exterior air and cool-dry interior air) reduces the amount of moisture in the outside air that is delivered to the interior. Heat and moisture are transferred to the exhaust air stream, reducing both the cooling and dehumidification loads associated with ventilation.*PRO*

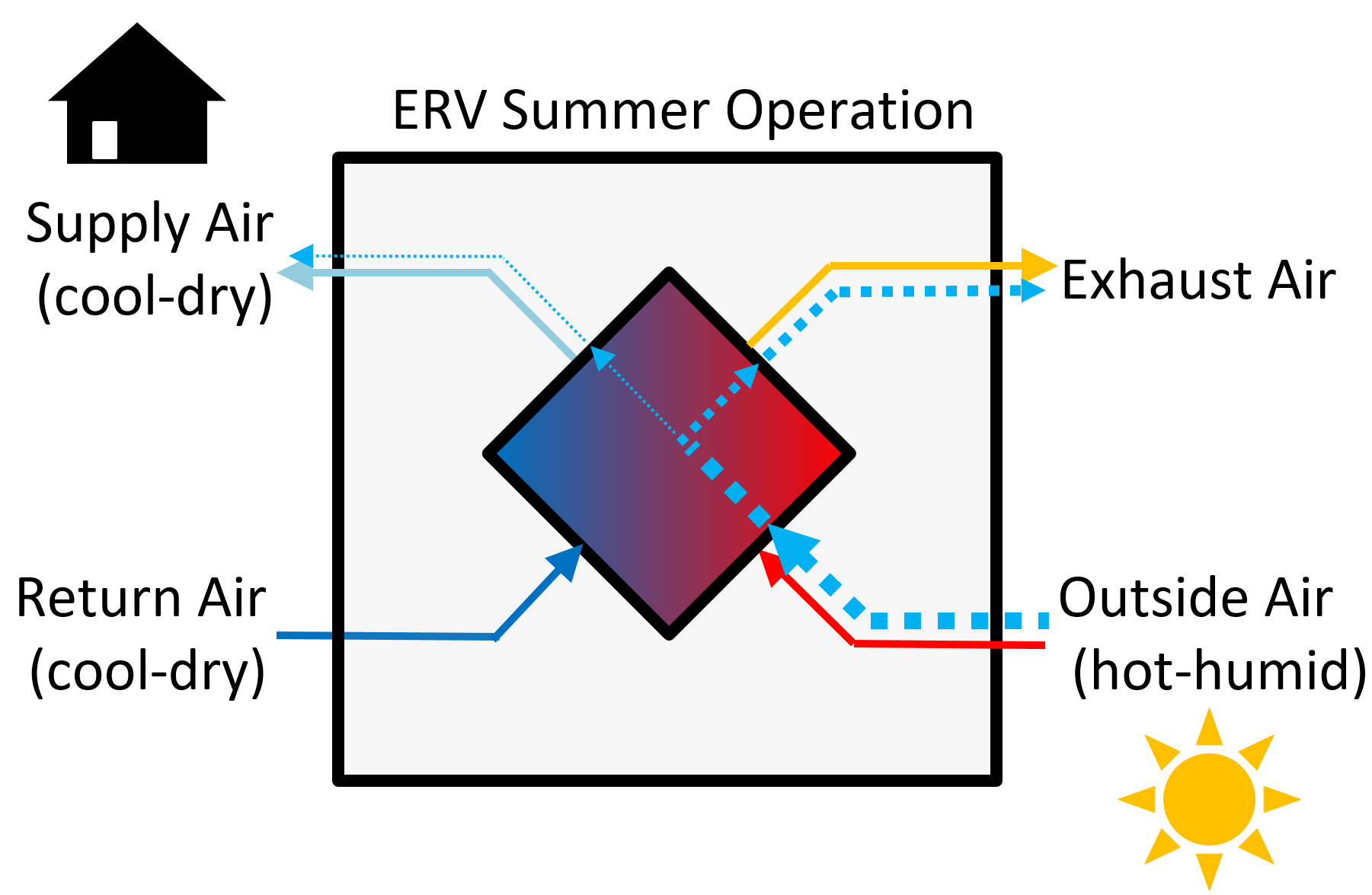

An ERV operating in the winter (cold-dry exterior air and warm-moist interior air) transfers both heat and humidity to the supply air at the recovery core. As a result, controlling interior moisture levels can be more challenging with winter operation of an ERV.*CON*

There are pros and cons of these primary operating conditions. Project teams should evaluate these situations identifying the highest risk scenario in relation to their climate and building program. The overarching Passive House design intent is to reduce heating and cooling demand, decrease equipment size, and minimize annual energy consumption, all while maintaining occupant comfort and building durability. Being mindful of the Passive House Design intent will help guide this conversation.

Let’s consider the primary operating conditions, starting with summer operation. Good Passive House design should result in decreased cooling loads and thus, smaller cooling equipment capacity. An HRV introduces additional moist air to the conditioned building in the summer. This may be problematic if there is a need for dehumidification, but there is no need for sensible cooling because the temperature in the space is already low. Since dehumidification will only happen when the cooling system is running (unless supplemental dehumidifiers are installed), the occupants might experience prolonged periods of high humidity and discomfort. Generally speaking, residential occupants are comfortable in higher summer setpoint temperatures only if the indoor relative humidity is kept between 40% and 60%. If the latent load cannot be met and the relative humidity increases beyond 60%, the majority of occupants will no longer be comfortable. As such, ERV operation in the summer may be desirable when you consider that an ERV will aid in removing moisture from the incoming air and help maintain a lower dehumidification load. This aligns with the Passive House design intent to maintain occupant comfort and reduce annual energy consumption.

Now let’s consider the winter operation. When evaluating the risk to building durability, winter building operation poses the highest condensation potential. During cold periods, heat is conducted through the building envelope. This can result in cold interior surfaces ideal for condensation, especially at the least efficient components, such as windows and doors. Condensation risk is increased by moisture generated from an occupant dense multifamily building; the higher the interior relative humidity, the higher the surface temperature where condensation can form. Even with high performance window components, the risk of condensation on windows and doors may be present when the interior relative humidity is high and surface temperatures are near the dewpoint. Mitigating the risk of interior condensation must be considered during the selection of an HRV or ERV.

Example: As a worst case, let’s assume an internal setpoint temperature of 68°F and window frame U-value of 0.275 Btu/hr·ft2·F (1.56 W/M2.K);

While these relative humidity levels may seem high, they can be easily realized in a new building with a dense population. It is not uncommon in our multifamily projects to have up to six people living in under 1000 ft2. The amount of moisture generated by occupant perspiration, cooking and showers, in addition to construction moisture in a new building, can easily drive interior relative humidity to these levels.

Even intermittent window condensation can be problematic from the perspective of mold growth and building durability. Condensation should be avoided in all buildings but should never occur in a Passive House where the design intent is focused on durability. These images of condensation all came from new construction projects in the last 5 years and were caused by all of the factors mentioned above:

Image 1, 2, 3: Condensation as a result of high indoor relative humidity and low ambient temperatures

Remember that an ERV operating during the winter transfers some of the moisture generated inside the building back to the incoming supply air. An HRV operating under the same winter conditions exhausts internally generated moisture, helping to control indoor relative humidity and condensation risk. This seems like a cut and dry argument for the exclusive use of HRV’s right? It is not that simple. The amount of moisture that is re-circulated by an ERV can be decreased with a centralized system through various control strategies and through the shear fact that the moist air from one apartment will be mixed with a much greater volume of air headed back to the ERV. This is in contrast to unitized ERVs, where the majority of the internal moisture gains would be returned back to the supply air of each apartment. If we assume that all apartments are not experiencing high humidity levels at all times, the shear mixing of these streams will reduce the amount of moisture that can be returned to any one apartment.

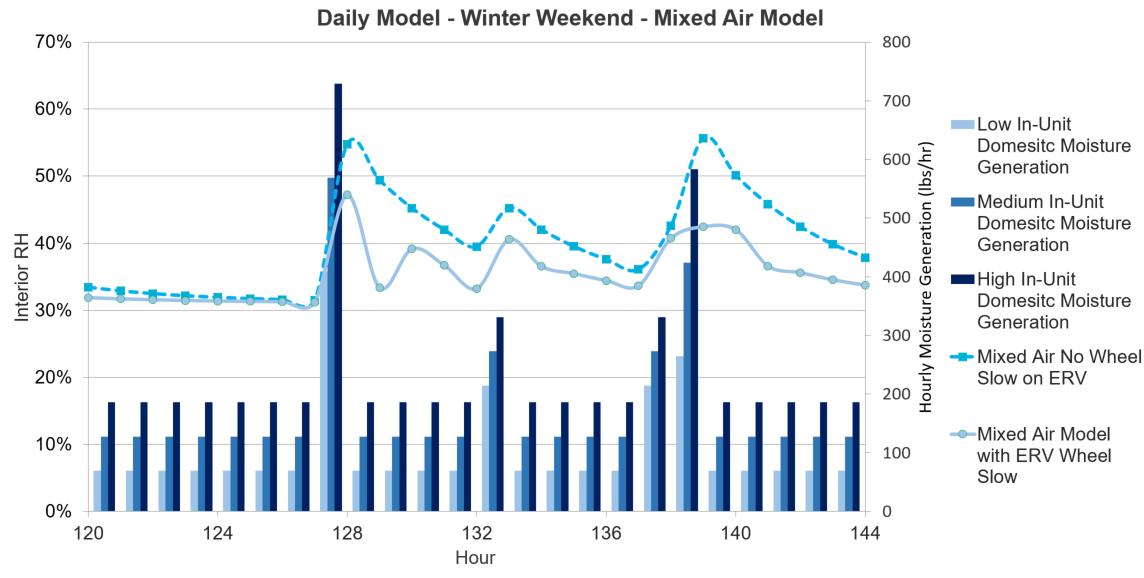

(For more info on HRV/ERV system arrangement see: Multifamily Passive House Ventilation Design Part 1: Unitized or Centralized HRV/ERV?). During periods when most apartments are likely to see increased humidity, such as the early morning and evening, moisture transfer of a central ERV can be controlled with partial recovery core bypass or by controlling the speed of the enthalpy wheel. This acts to reduce the latent moisture transfer efficiency from return to outdoor airstreams. As a consequence the sensible heat transfer efficiency is also reduced temporarily. Our analyses show supply air relative humidity can be reduced 10 – 15% with moisture recovery control. This additional functionality makes central ERVs a viable option when applied to a multifamily Passive House in the winter.

Example: The data shown below in Figure 1 represents a multifamily Passive House building operating a central ERV in a New York City winter. The analysis assumes an equal mix of low, medium, and high humidity generation scenarios, demonstrating possible apartment types in a multifamily building. The interior relative humidity peaks in the morning and evening at 55%. With the addition of moisture recovery control and a decreased enthalpy wheel speed, the peak relative humidity is decreased 10 – 15%, resulting in an interior relative humidity of 45%.

Figure 1: Winter building operation showing decreased supply air relative humidity resulting from central ERV enthalpy wheel speed reduction

There is no prescriptive path for HRV or ERV selection. However, centralized ERVs can be operated to control supply air moisture content in both winter and summer. This makes ERVs an attractive option for multifamily Passive House buildings in New York City.

*click here to read Part 1 of this blog

Contributors: Dylan Martello, Senior Building Systems Consultant; Thomas Moore, Building Systems Analyst

Steven Winter Associates