Blog

Technical standards referenced by federal, state, and local laws and building codes include design criteria developed to ensure that operable parts are accessible.

Operable parts designed to be used by building occupants, including but not limited to, thermostats, dispensers, light switches, fire alarm pull stations, etc., must be located so that they are accessible to everyone. Technical standards referenced by federal, state, and local laws and building codes include design criteria developed to ensure that operable parts are accessible. A 30 x 48 inch clear floor space is required to be positioned at the operable part to support one of two types of reaches: a forward (perpendicular) or a side (parallel) reach. Of the two reach types, each can be unobstructed or obstructed. Unobstructed forward and side reaches do not require reaching over an element to access an operable part. Conversely, obstructed forward and side reaches require reach over an element, such as a countertop or shelf, to access an operable part. Of all the reaches to operable parts, the obstructed forward reach is the most challenging to design and construct. As we always say, the devil is in the details, so proper detailing of the obstructed forward reach is critical to nail down in design.

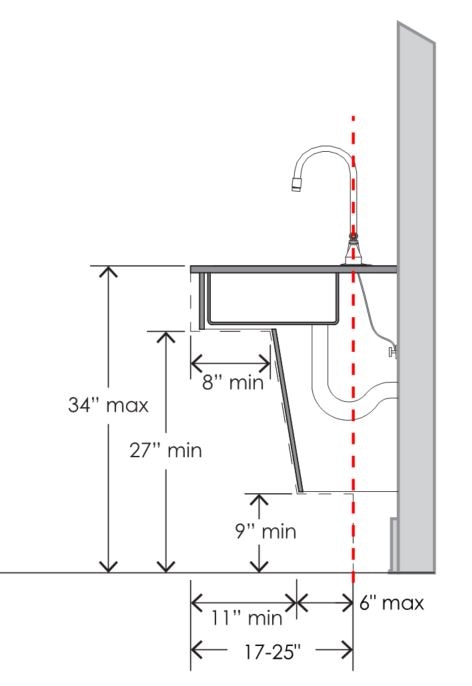

To support an obstructed forward reach to an element, such as the reach to faucet controls located at the back of a sink, open space below the obstruction (i.e., knee and toe clearance) must exist to allow a person using a wheelchair to roll into the clear space below the sink and reach forward to access the faucet controls. The same principle applies to a medicine cabinet or outlet mounted on the backsplash. Without compliant knee and toe clearance provided below an obstruction, a person using a wheelchair cannot access operable parts located over an obstruction utilizing the forward approach.

When designing for forward approach, more recent technical standards like the 2010 ADA Standards and the A117.1 Standard require that the 30 x 48 inch clear floor space positioned to support the forward reach extends between 17 and 25 inches below an obstruction. If knee and toe clearance below an obstruction is limited to 17 inches, then operable parts cannot be located beyond 17 inches, measured from the front edge of the obstruction. Stated differently, compliance is not achieved if reach beyond the toe line is required. For example, if a bathroom lavatory is 23 inches deep and the knee and toe clearance is designed so that a person using a wheelchair can pull under the sink for a full 23 inches, then reach to the faucet controls can be accommodated because the wheelchair can roll under the sink for a full 23 inches; reach beyond the toe line is not required. However, if a bathroom lavatory is 23 inches deep and the knee and toe clearance is designed so that a person using a wheelchair can pull under the sink for only 20 inches, then if faucet controls are located more than 20 inches beyond the front edge of the sink, they are not accessible. Faucet controls in this case must be located no more than 20 inches from the front edge of the sink for them to be accessible.

What we often find is that although designs include knee and toe clearance below obstructions, there are operable parts located above those obstructions that are not accessible because they require reach beyond the limit of the toe line. Remember – it is important to consider easily overlooked requirements like reach depth when designing millwork or coordinating shop drawings for cabinetry. It’s all about the details.

We’re here to help! Contact us to learn more about our accessibility consulting services.

Peter Stratton