Blog

While automatic doors have always been a good option for providing greater access to people with disabilities, hygiene concerns associated with the spread of disease have presented another argument for their use.

As the country continues to confront the realities of the COVID-19 pandemic, the way we navigate spaces is changing. One of these changes is the way we interact with common use objects that traditionally require hand-operation, like doors. While automatic doors have always been a good option for providing greater access to people with disabilities, hygiene concerns associated with the spread of disease have presented another argument for their use. The rise of touchless technology as a result of this pandemic will increase the use of automatic doors not just for accessibility or convenience, but for public health as well. For anyone considering incorporating automatic doors into their designs, either for new construction or as a retrofit, here are some important things to consider:

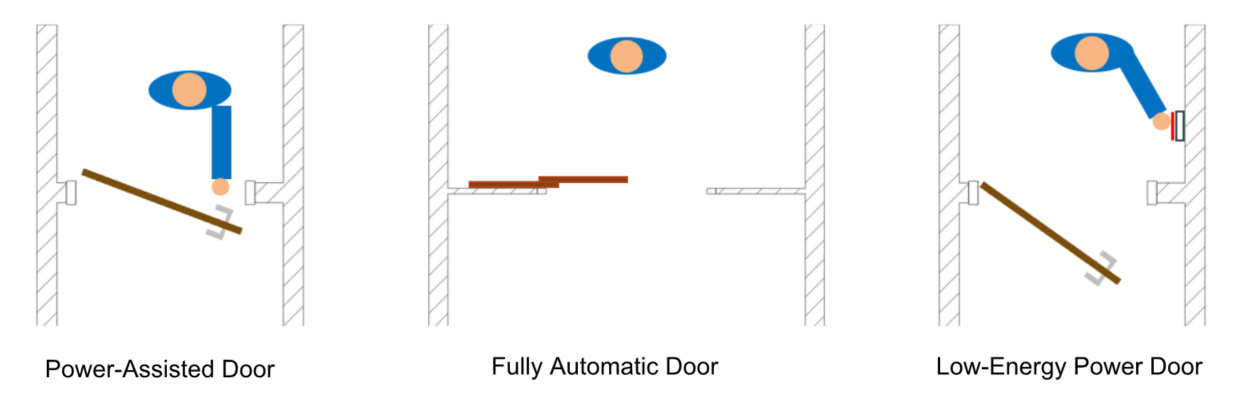

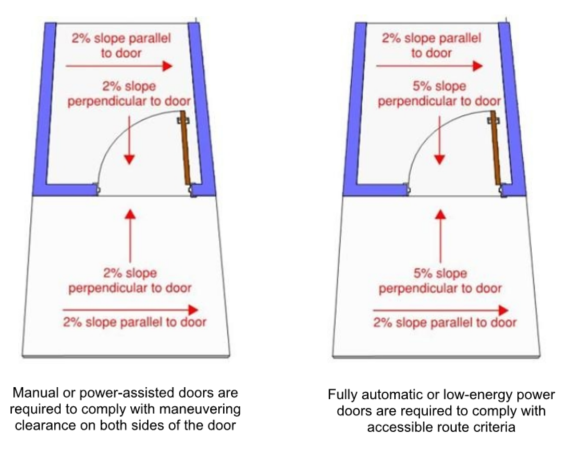

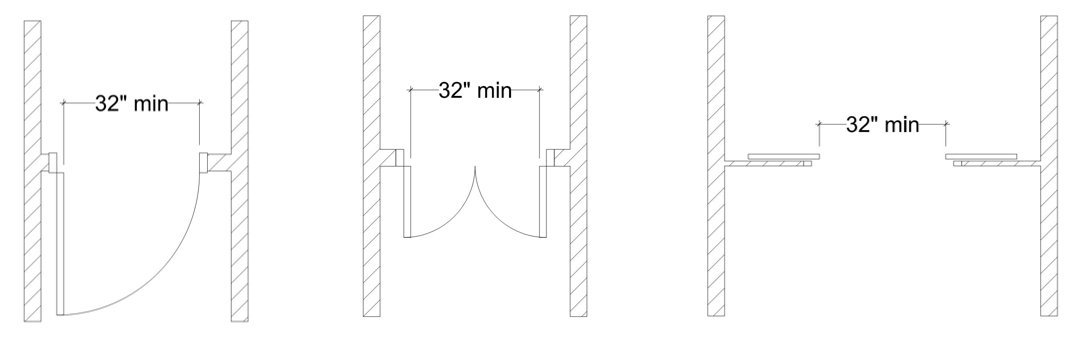

There are three types of automatic doors: power-assisted, fully automatic, and low-energy operated.

The type of automatic door used will trigger different accessibility requirements.

The parts needed to make an automatic door work depend on the use. Fully automatic doors may only need an automatic operator, while more complex door systems may require additional parts.

The operator is the main part of the door opening system that houses the motor and has either an articulating arm or sliding mechanism. The operators can either be electromechanical or electrohydraulic. Electromechanical operators are used on doors where the automatic opening function is the primary use. Electrohydraulic operators are used on doors that are primarily intended for manual operation but can also be operated via wall switches or motion sensors. These operators incorporate a standard door closer with the automatic operation.

Low-energy doors require an actuator to engage the operator. The actuators can be hardwired or wireless. In addition to push buttons, the actuators can be hands-free or “wave-to-open”. Where a latch is provided, a method to unlatch the door when the actuator is depressed is required. Either the strike or the latch can be electrified to release when the automatic door is activated. In addition, a power supply box is required, which houses the AC/DC power converter for the latch, the backup battery for the whole system, and the relay board that ties the operator, actuator, and latch release together. Ventilation is required for the power supply box, so its installation location is important to consider.

As COVID-19 changes the way we design, we must be mindful of the way these changes affect accessibility and impact the way we navigate the built environment. Solutions like automatic doors, when installed with proper planning, have the potential to positively impact public health and safety while also providing greater access to a person with a disability.

We’re here to help! Contact us to learn more about our accessibility consulting services.

Contributor: David Mike, Accessibility Specialist

Peter Stratton